- 2023-01-11

Reasons for slow heating of metal molds

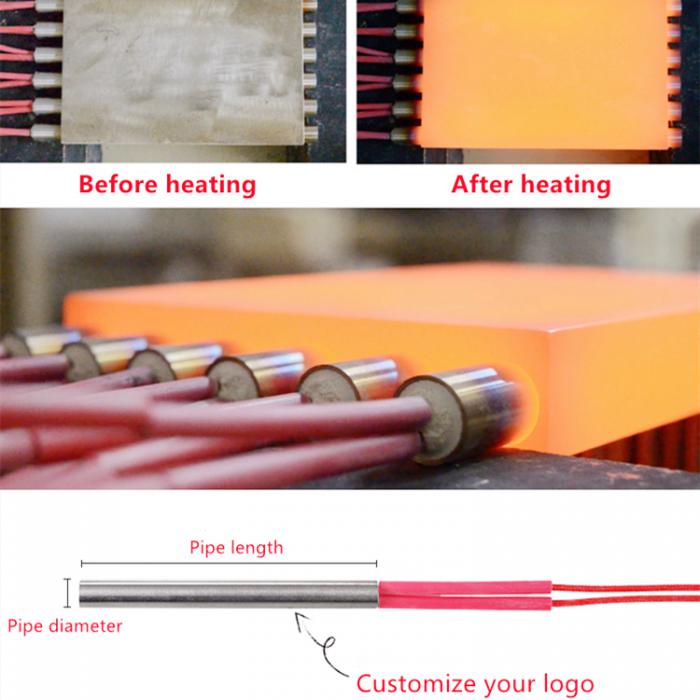

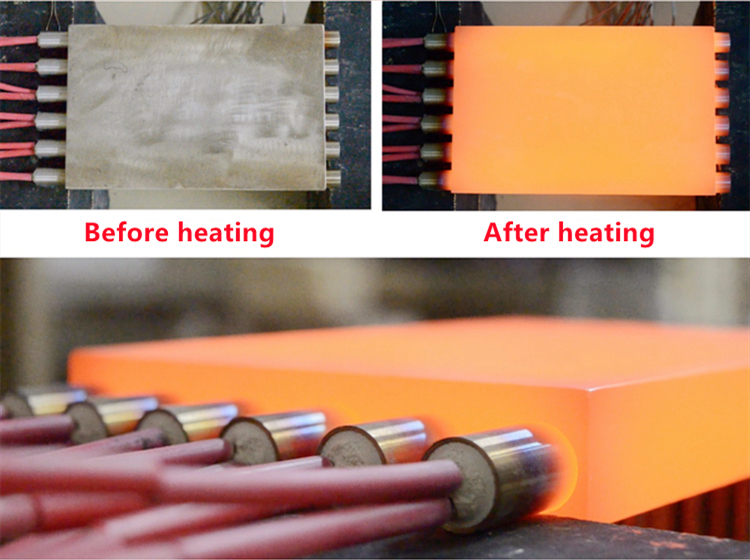

Cartridge heater installed in the metal mold, sometimes you will find that the temperature rise speed does not reach the expected situation, such as the original hope that the mold from room temperature to 150 degrees within 1 hour, the results of 2 hours to reach 80 degrees, this situation caused by how? Today we will analyze from various aspects: 1.

1. Insufficient power.

Cartridge heater power design is not enough, it may be because the heater itself is too low power, or the number of cartridge heaters is not enough to cause the overall power is too low, which will cause the mold heating speed is not as fast as the cooling speed, heating speed greatly reduced.

2. Uneven distribution of cartridge heater position.

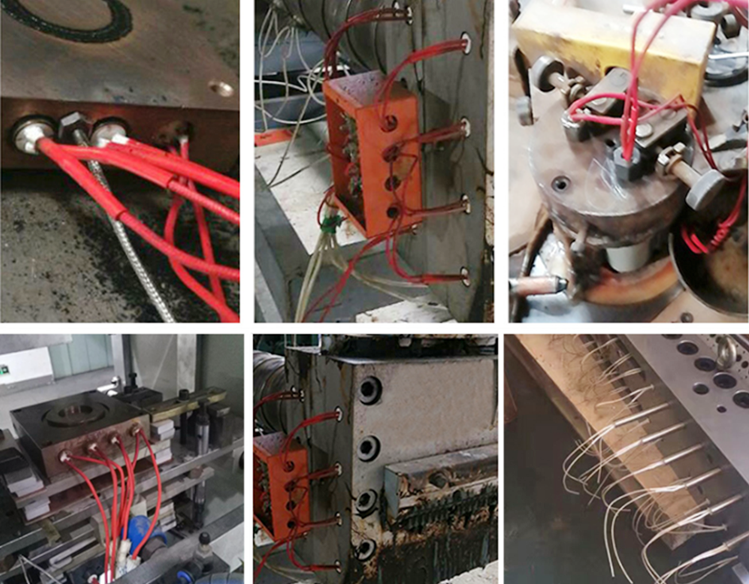

For larger molds or products, try to disperse the arrangement when distributing the cartridge heater, if it is too centralized, it may lead to the temperature on the side far from the cartridge heater cannot reach the requirement.

3. Whether there is a wrong connection of power.

The rated power of the cartridge heater can only be achieved at the rated voltage, so if the power supply is connected wrongly (for example, the heating tubes originally connected in parallel are connected in series), the input voltage of the heating tubes may be too low, so that the output power of the heater will be greatly reduced.