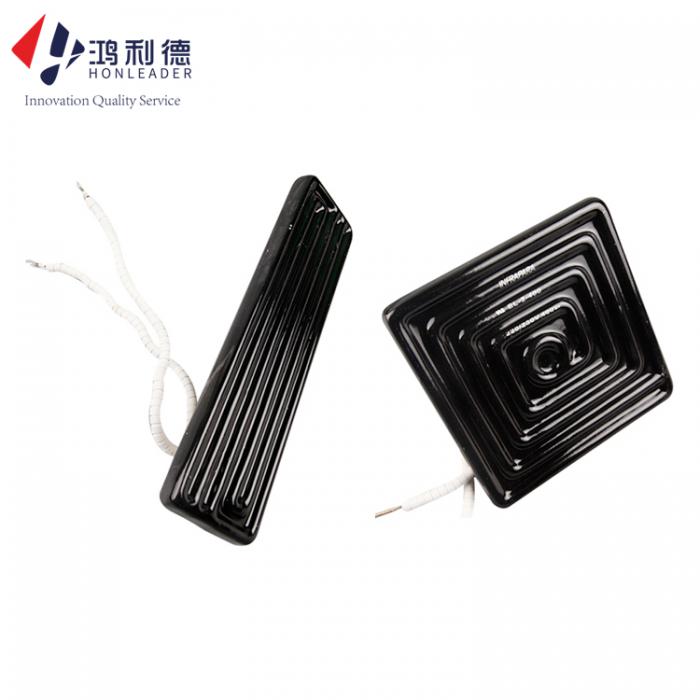

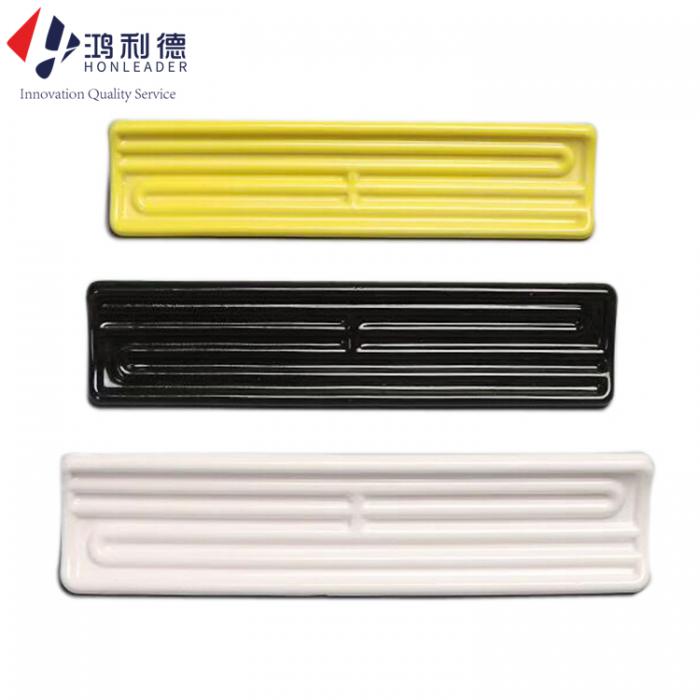

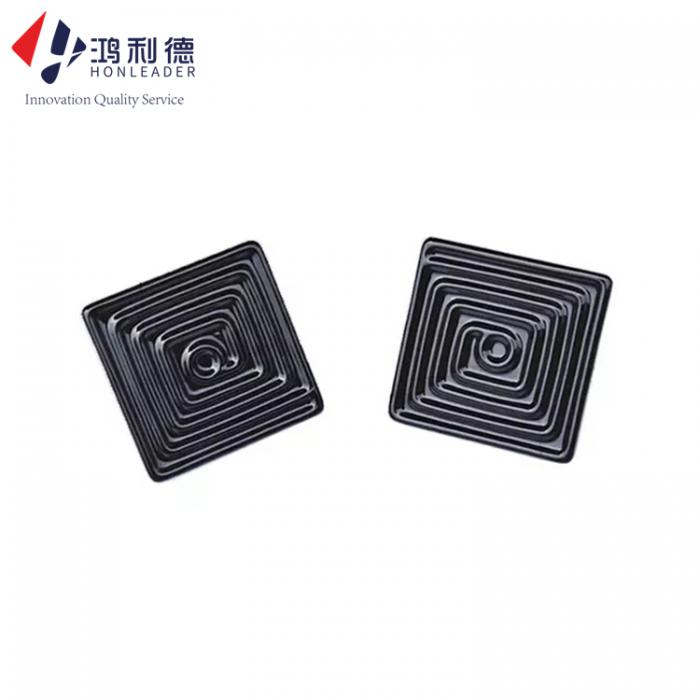

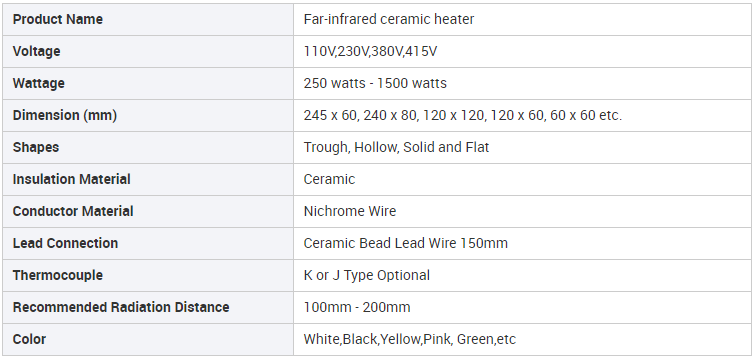

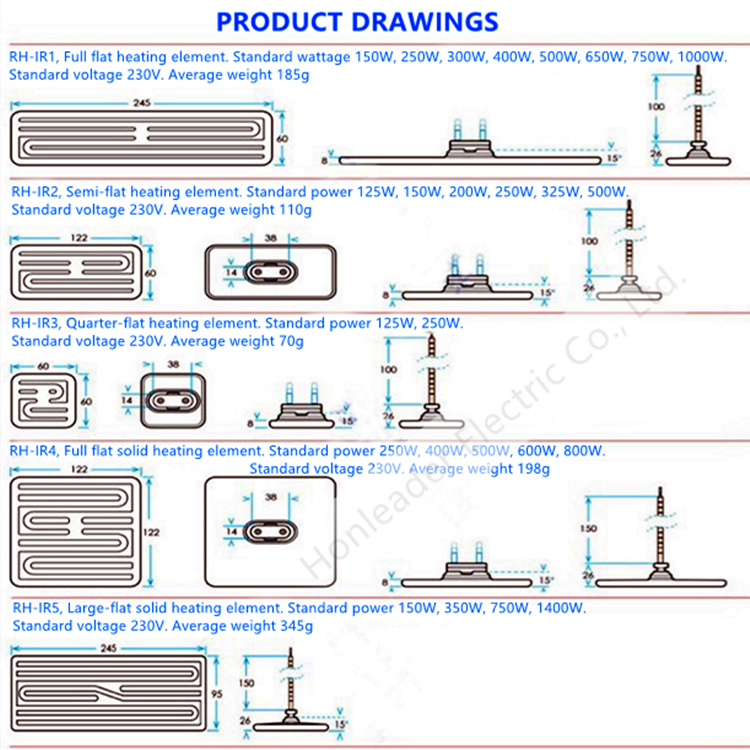

| Name: | Curing Machine Infrared Ceramic Heater Plate |

|---|---|

| Type: | Infrared Heater |

| Voltage: | 110V/220V/380V/415V/ Customization available |

| Wattage tolerance (): | ±3 |

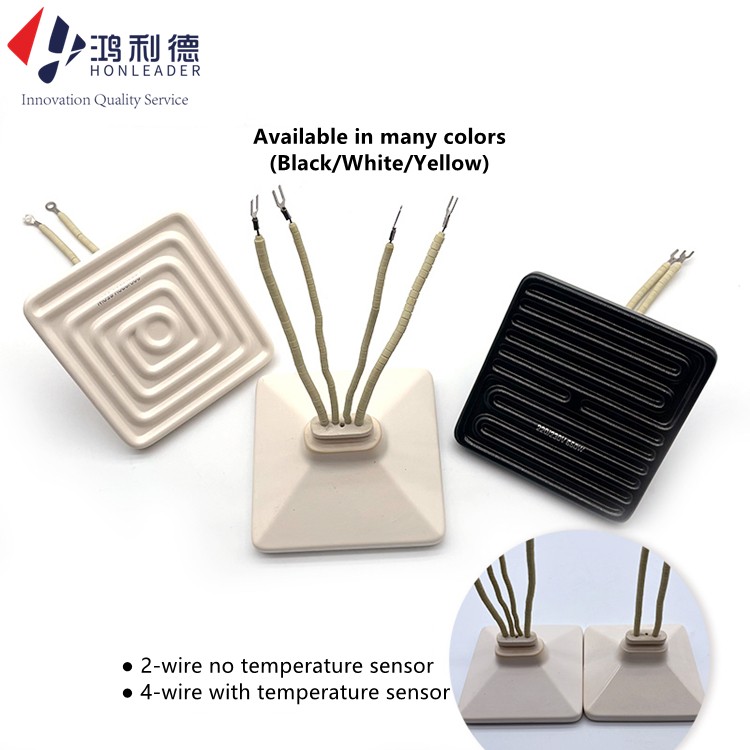

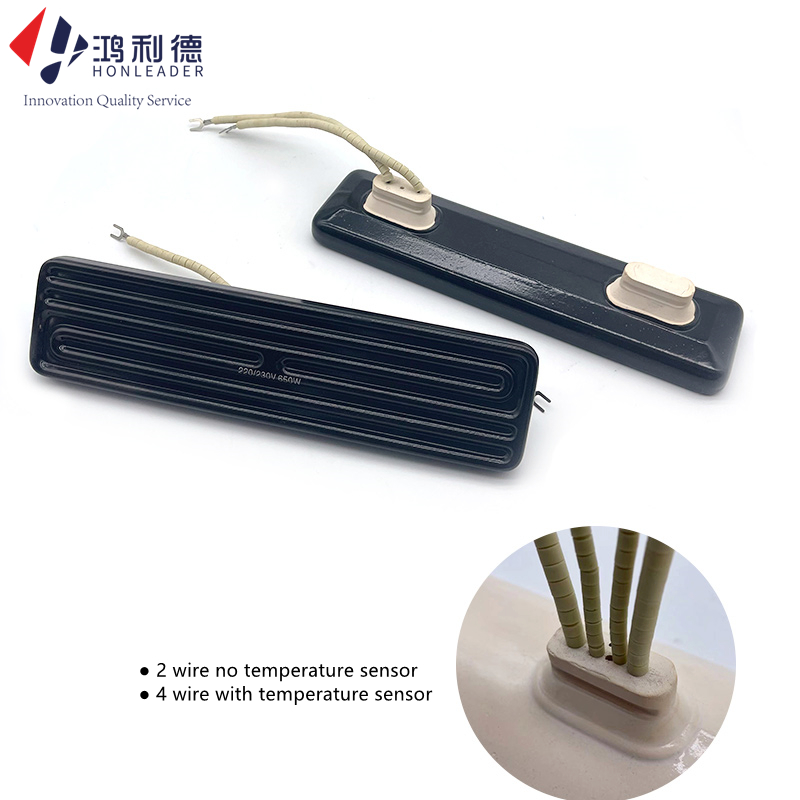

| Shape: | Hollow/Flat/Curved/Solid,etc |

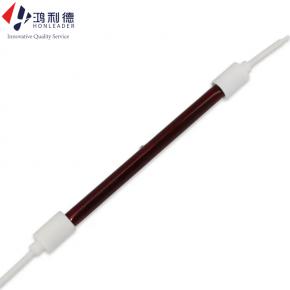

| Resistance wire: | Cr20Ni80 |

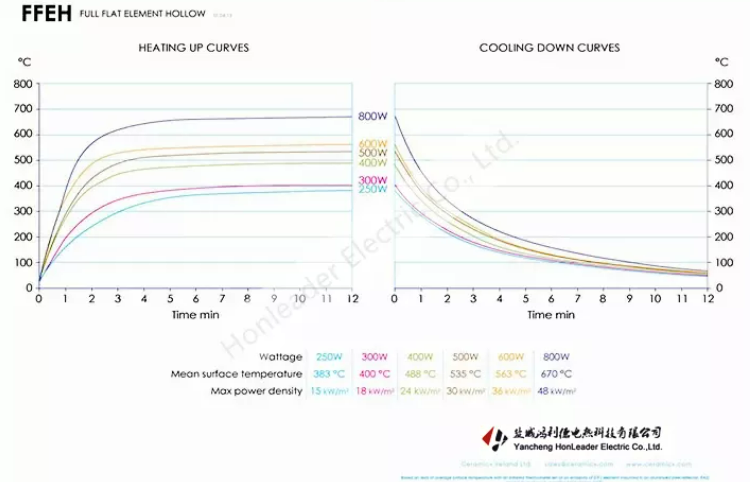

| Working Temperature: | Max 800°C, depend on watts |

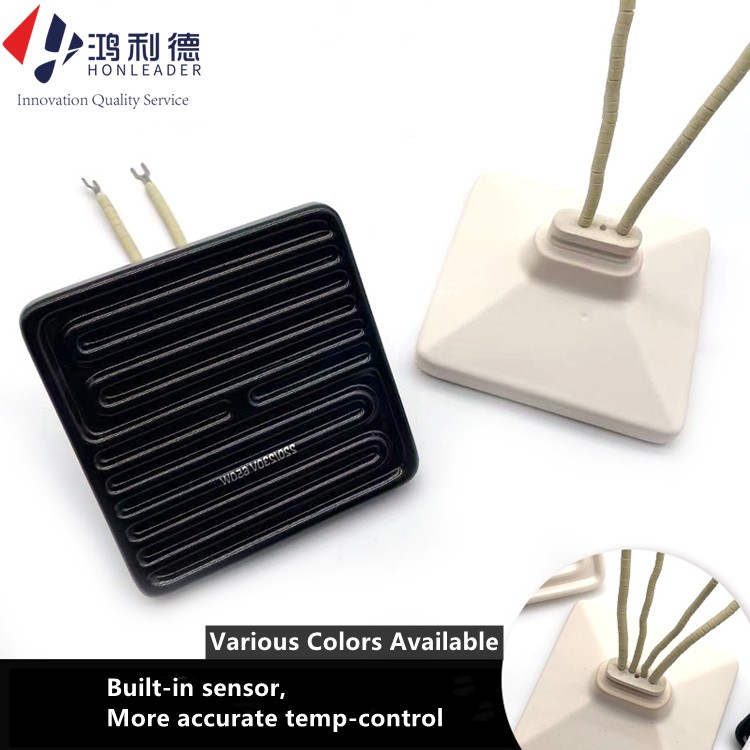

| Color: | White,Black,Yellow,Pink, Green,etc |

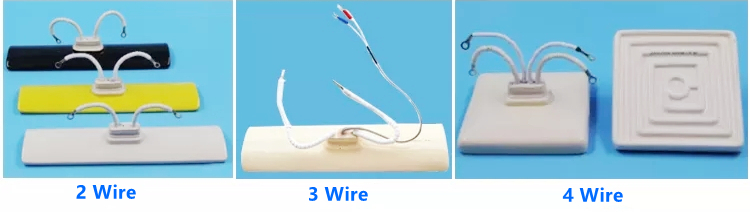

| Lead Connection: | Ceramic Bead Lead Wire 150mm |

| Color temperature (K): | 800~2500K |

| Average service life (H): | ≥5000H |

| Accessories for option: | Reflector or Thermocouple available |

| Length (mm): | 100mm~3000mm Available |

| Warranty: | 2 Years |

-

● Infrared Ceramic Heater use conductor containing more than 95% silicon and quartz glass hich can resist 1800°C as main material. The spiral Cr20Ni80 resistance wire is cast into the conductor. It generates heat through heat conduction and heat radiation, and has a certain penetrating power. ● Infrared Ceramic Heater operate in the temperature of 300°C to 700°C (572°F - 1292°F) producing infrared wavelengths in the 2 - 10 micron range. Most plastics and many other materials absorb infrared best in this range, which makes the ceramic heater the most popular infrared radiant emitter on the market.

● With its advantages in thermal efficiency, energy conservation and radiation safety, infrared ceramic heater widely used in: Vacuum blister machine, Coating machine, Automobile interior molding machine, Medical equipment and Smokeless barbecue oven, etc.

● Food industry: food drying, food heating, food packaging material molding, food high temperature sterilization ● Printing industry: drying and curing process of glue and ink ● Glass industry: glass annealing and coating drying process ● Packaging industry: PET blowing, laminating, ink drying process ● Shoemaking industry: glue activation and drying process ● Furniture industry: rapid drying process for water-based/oil-based coatings and paints ● Rubber industry: surface modification, plastic softening, molding process ● Photovoltaic industry: battery silicon wafer welding, sintering, substrate drying, spray preheating process ● Automobile industry: Sunlight simulation environment warehouse, sealing tape/wire harness heating, whole vehicle painting and baking paint, body part patching and baking process ● Textile industry: coating drying, fabric preheating, drying, pressing and adhesive activation process ● Household appliances: disinfection cabinets, convection ovens, toasters, toasters, and food ovens,etc ......

Hits: 【Print】