| Name: | Silicone Heater For Valve Heat Insulation |

|---|---|

| Voltage: | 5v,12,24v,48v,110v,120v,220v,380v or Customized |

| Wattage: | Customized |

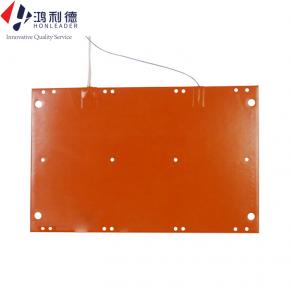

| Thickness: | Conventional 1.5mm-3mm, can be thicker |

| Minimum size: | 10mmx 20mm |

| Maximum size: | 1200mm x 10000mm |

| Continuous use temperature: | ≤200℃ |

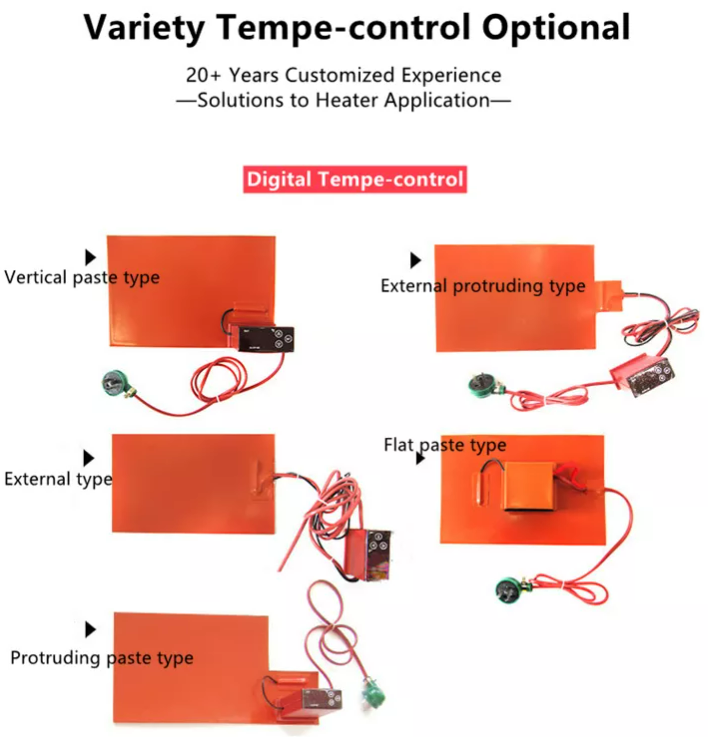

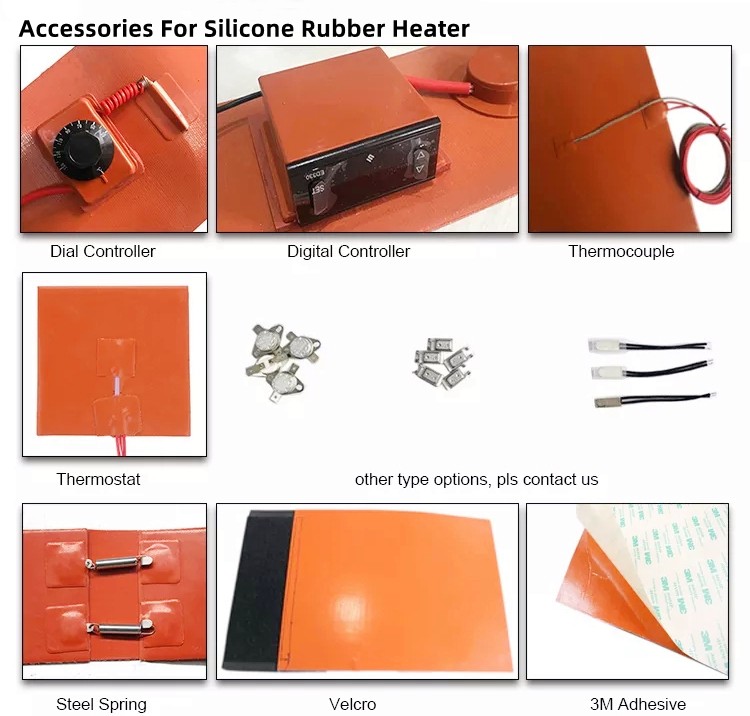

| Temperature control: | Digital display/Manual knob temperature control available |

| Wattage density: | 0.01-2w/cm², recommended power density: 0.1-0.8w/cm² |

| Wattage deviation: | ±3 |

| 3M adhesive:: | Yes or No |

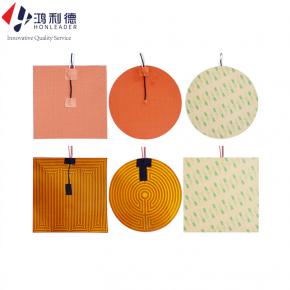

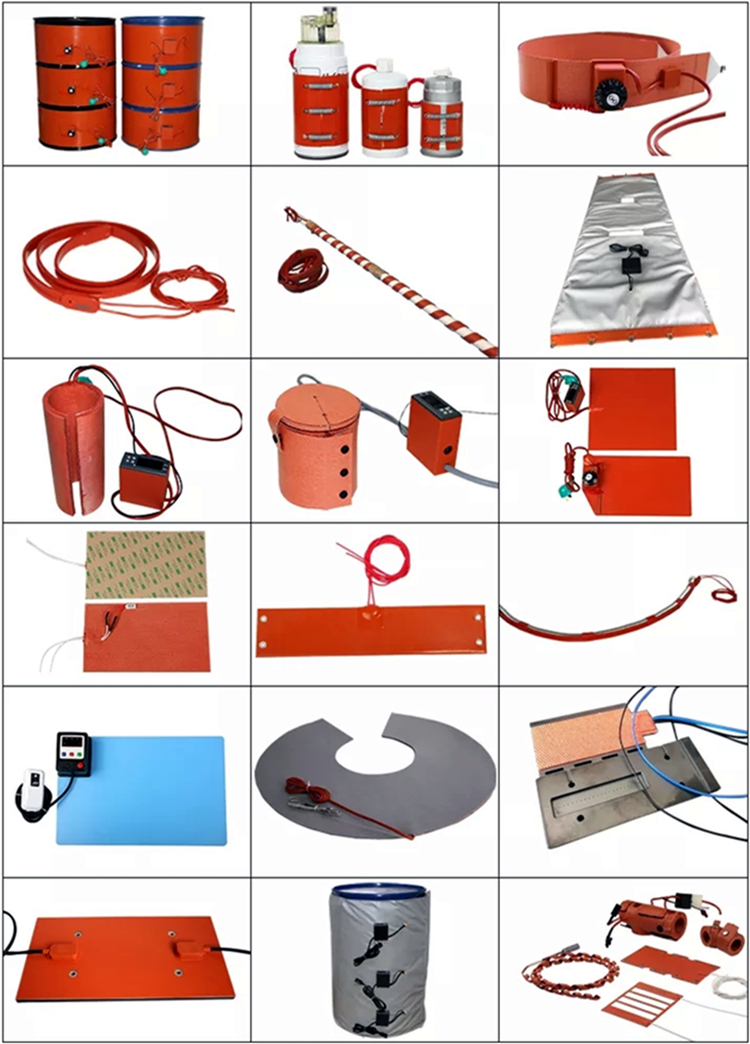

| Shape: | Any shape Customized |

| Mechanical compression: | 100KG/cm² |

| Wire tension: | 80N |

-

● Silicone rubber heater has good flexibility, mainly composed of nickel-chromium alloy heating wire and silicone rubber high temperature insulation layer (Standard thickness is 1.5mm). ● Silicone rubber heater has the characteristics of fast heating, uniform temperature, high thermal efficiency, high strength, convenient use, safe life of up to 5 years, and not easy to aging. It can be in close contact with the heated object. ● The heating element of the silicon rubber heater can be wound or etched foil process. The winding element consists of a resistance wire wound on a glass fiber wire to provide support and stability. The etched foil heater is made of thin metal foil as a resistance element, the heating power can reach 1.2W/CM2, and the heating effect is more uniform. To ensure that the heat is transferred to any place needed. ● Silicone rubber heaters can be used in humid, non-explosive gas occasions, industrial equipment pipelines, tanks, etc. for mixing and heat preservation (oil drum heaters), and can be directly wound on the surface of the heated object. It can be used as medical equipment (such as blood analyzers, test tube heaters, medical care shapers, body shaping and slimming belts to compensate for heat, etc.).

Voltage 5v,12,24v,48v,110v,120v,220v,380v or Customized Wattage Customized Thickness Conventional 1.5mm-3mm, can be thicker Minimum size 10mmx 20mm Maximum size 1200mm x 10000mm Continuous use temperature ≤200℃ Instantaneous max-tempe 280℃ Temperature control Digital display/Manual knob temperature control available Wattage density 0.01-2w/cm², recommended power density: 0.1-0.8w/cm² Heating wire process Etching process, the temperature difference within 3-5℃. Wattage deviation ±3% Insulation withstand voltage 1500V/min Insulation resistance ≥1000MΩ Mechanical compression 100KG/cm² Wire tension 80N Shape Any shape Customized Any request, please do not hesitate to let me know.

1. Heat transfer machine 2. Oil drum heating

3. Battery heating 4. 3D Printer heating bed

5. Baking cup (pan) machine 6. Heat-sealing machine heating sheet

7. Heating of chemical pipelines 8. Heating and heat preservation of medical equipment

9. Large equipment heating 10. Semiconductor processing equipment

11. Food service equipment 12. Lab analytical instruments

13. Heating and heat preservation of various mechanical instruments

14. Medical equipment, such as blood analyzers, respiratory therapy devices and hydrotherapy

15. Antifreeze for Aerospace, Aircraft instruments and Hydraulic equipment

......

(Part for your information, in fact, silicone rubber heaters can be used in many industries that require heating, heat preservation, dehumidification and antifreeze)

How to order :

1. What substance do you need to heat? (Such as water, oil, resin, iron, copper, air, plastic, nitrogen, etc.)

2. How much of this substance do you need to heat?

3. What is the power supply voltage?

4. What is the initial temperature?

5. What is the final target temperature?

6. After the heater starts, how quickly do you want to reach the final temperature?

7. Please describe the application of the product in detail.

Hits: 【Print】