- 2023-01-11

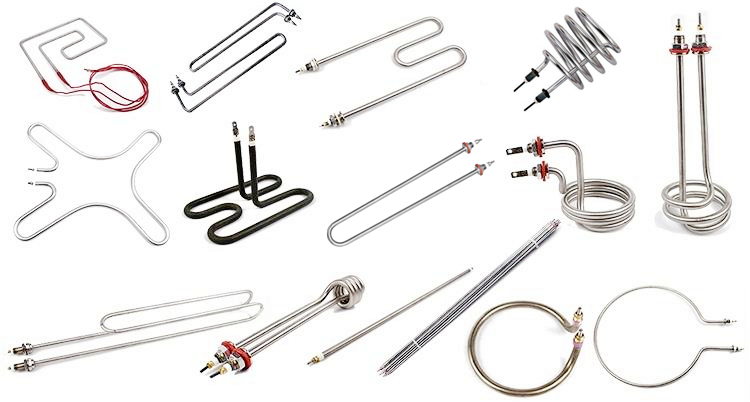

Common types of tubular electric heaters

Fin electric heating element is a consumption of electrical energy converted into heat energy, so as to heat the heated medium. In the work, the low temperature fluid medium through the pipe under pressure into its input port, along the specific heat exchange flow channel inside the electric heating vessel, using the path designed by the principle of fluid thermodynamics, take away the high temperature heat energy generated in the work of the electric heating element, so that the temperature of the heated medium rises, and the outlet of the fin electric heating tube gets the high temperature medium required by the production process.

The finned tubular electric heating element, is wound on the surface of the ordinary element metal heat sink, compared with the ordinary element heat dissipation area expanded by 2 to 3 times, that is, the surface power load allowed by the finned element is 3 to 4 times that of the ordinary element. As the length of the element is shortened, the heat loss itself is reduced, and under the same power condition, it has the advantages of fast temperature rise, high thermal efficiency, long service life, small size of heating device and low cost. It can be installed in the blowing duct or other static and flowing air heating occasions.

Flange heater (also called immersion heater), is the use of U-shaped stainless steel tubular electric heating element, according to the design specifications for heating different media, in accordance with the power configuration requirements assembled on the flange cover, inserted into the material to be heated, the heating element work emitted a large amount of heat conduction to the heated medium so that the medium temperature rises, to achieve the required process requirements. When the medium temperature reaches the set value of process requirements, the control system adjusts the output power of electric heater according to the temperature sensor signal after PID operation to realize temperature control for the resistive load of heating element. Make the medium temperature uniform, to achieve the required requirements; when the heating element over temperature or low level, the heating element interlock protection device immediately cut off the heating power to avoid the heating element burned, to extend the service life.

Flange electric heating tube is mainly for petroleum, chemical, food, machinery and other industries of various types of storage tanks, containers, oil tanks in material insulation and heating. The connection can be flange type or threaded end seal.

Titanium tube heater is a titanium tube as a shell, along the center of the tube axially evenly distributed electric heating alloy wire whose gaps are filled with compacted magnesium oxide sand with good insulation and thermal conductivity, the two ends of the tube mouth with silicone or ceramic seal, this metal electric heating element dedicated to high corrosion liquid.

Titanium tube heater has a simple structure, high mechanical strength, high thermal efficiency, safe and reliable, easy to install, long service life, etc.. Widely used in a variety of highly corrosive liquids. Titanium material has a small specific gravity, widely used in heating water, nitrate solution, acid solution, alkali solution, practice has proved that titanium in the production of anti-corrosion equipment applications, high efficiency, long life, in the application of electroplating equipment, does not affect the plating solution can greatly improve the benefits of the plating industry. The effective length of the electric heating element must be fully immersed in the liquid to use.

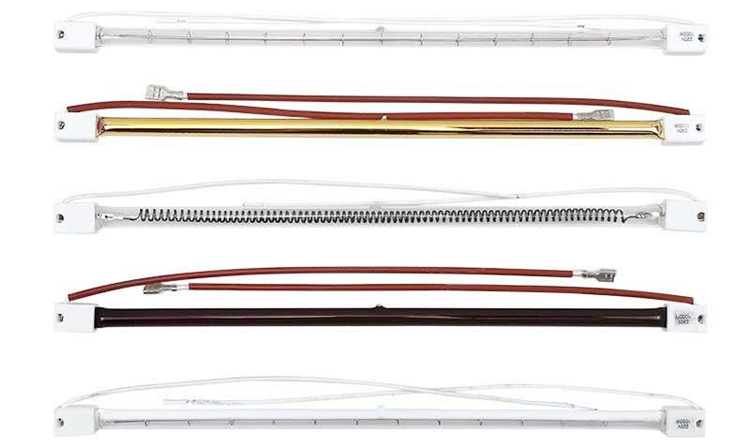

Halogen quartz heaters, also known as carbon fiber heaters, infrared heaters, infrared electric heaters, carbon fiber infrared heaters, carbon fiber infrared heaters, etc. The most common for carbon fiber quartz heater, Cr20Ni80 quartz heater, and tungsten halogen quartz heater. It is a resistance heating wire placed in the quartz tube, the tube is sealed by vacuum, and the resistance wire is connected to voltage, so that the resistance wire heats up and generates heat. Our products use imported tungsten wire/carbon fiber/Cr20Ni80 heating resistance wire, which has the advantages of large power margin, high temperature resistance, high heat capacity, long service life, and the power can be adjusted at will.

Teflon immersion heater is a new type of strong corrosion resistant electric heating tube for all kinds of corrosive liquid heating. It has excellent anti-aging property and better winding performance, and adopts low surface load design. The joints are fully enclosed acid and alkali resistant, and the non-heating section and overheating safety protection system are completely customized according to the customer's needs. Complete to ensure that the heater is not easy to burn, long service life, fully sealed, no corrosion, no leakage, with grounding protection, safe and reliable. The applicable temperature is below 110°C.

Teflon immersion heater has the advantages of high thermal efficiency, energy saving and power saving, high cost performance, and can be designed in various structural forms, such as spiral type, L type, U type, W type, mosquito type, combination type, etc. We can undertake non-standard products in voltage, power, specification size and product shape, as well as wiring method, can design the best heater solution according to the customer's needs, welcome to come to the picture to sample custom production.

Infrared radiation heater is an electric heating element enclosed in a protective sleeve energized to generate heat, and the sleeve indirectly radiates heat to the furnace lining and the workpiece being treated, which is widely used in various heating furnaces in the heat treatment industry. The electric heating alloy material used for infrared radiation heater should have high resistivity and high electric heat conversion rate. As the radiation tube is placed in the casing, the heat transfer process is different from the general open type electric heating element, which has a large heat shield, and the temperature of the element must be controlled during the heating process to prevent the element from overheating. Radiation tube closed heating, the surface temperature of the electric heating element than the furnace chamber temperature is about 100 ℃ -150 ℃. So in the selection of materials to analyze the furnace temperature, furnace temperature atmosphere, choose the correct heating materials.