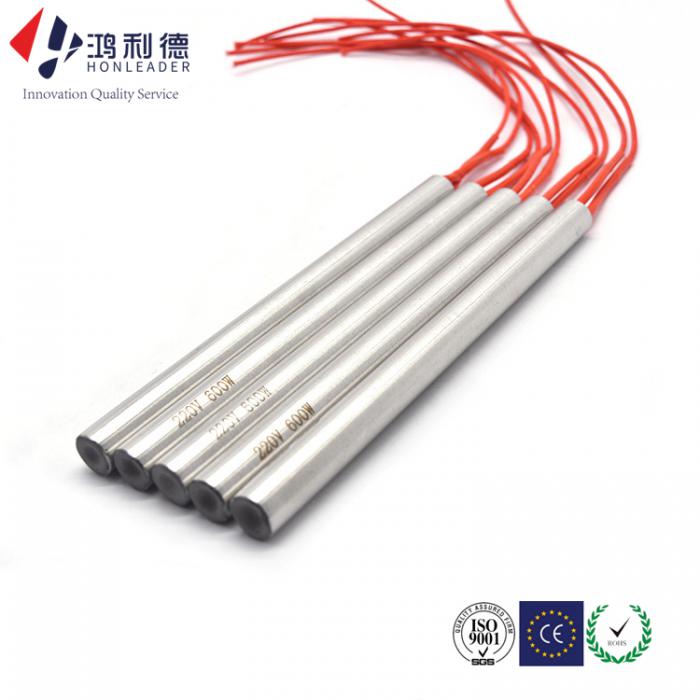

| Name: | Cartridge Heater |

|---|---|

| Voltage: | 12V/24V/36V/110V/220V/240V/380V/418V |

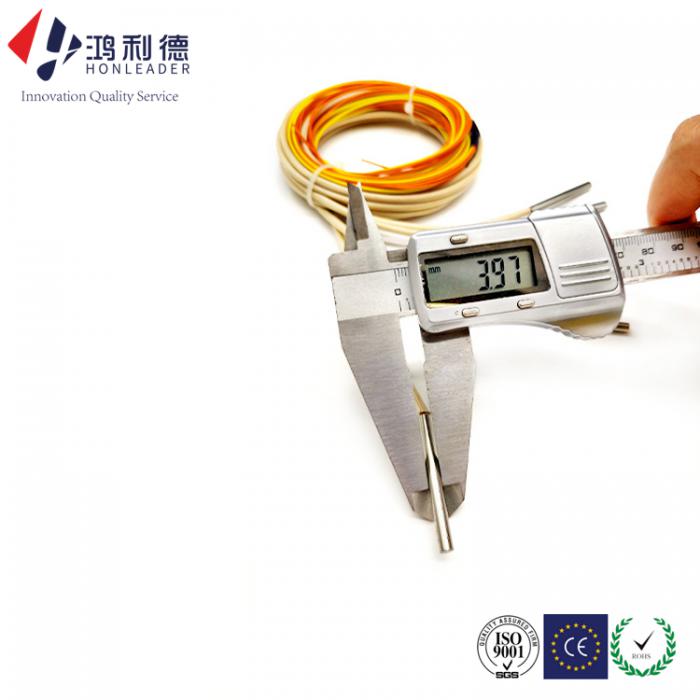

| Tube diameter: | From 2.0mm to 30mm |

| Sheath Material: | Seamless SS304/316/321/ Incoloy800/840 alloy, etc. |

| Insulation resistance (cold):: | ≥ 500 MΩ |

| Diameter tolerance: | -0.02mm |

| Max operating temp: | 870ºC(1600F) |

| Diameter tolerance: | +0.05mm -0.1mm (+.002 |

| Dimension(LWH): | Cutomers Request |

| Resistance: | NiCr80/20 |

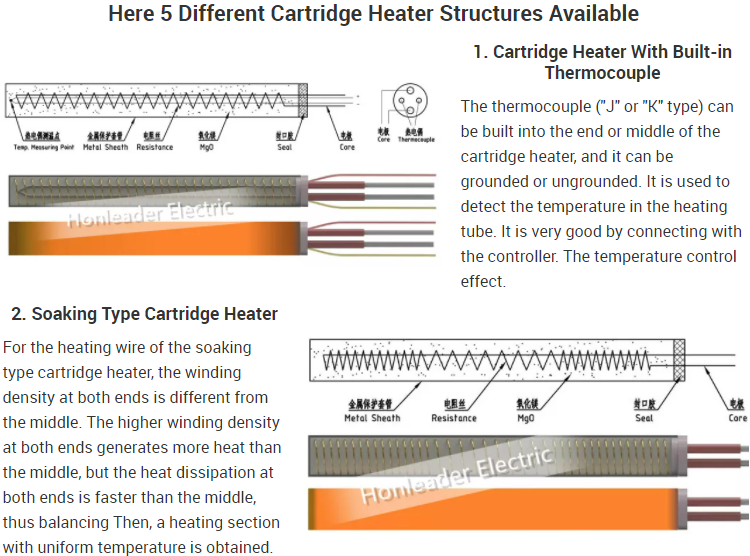

| Thermocouple Location: | type J or K are available |

| Thermocouple Location: | Disc End, Sheath, Center of Heater |

| Wattage Tolerance: | ±3 |

| Length tolerance: | ± 2 or 3.2mm (1/8”) |

-

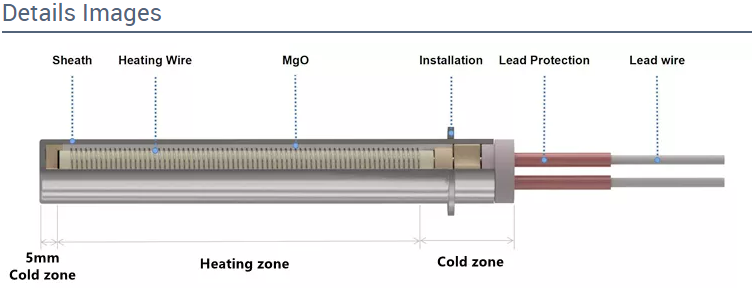

● Electric heater cartridge is a piece of equipment, made of MgO powder or MgO tube, ceramic cap, resistance wire(NiCr2080),High temperature leads, seamless stainless steel sheath(304,321,316,800,840)

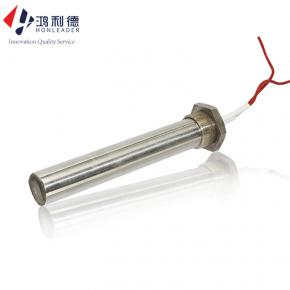

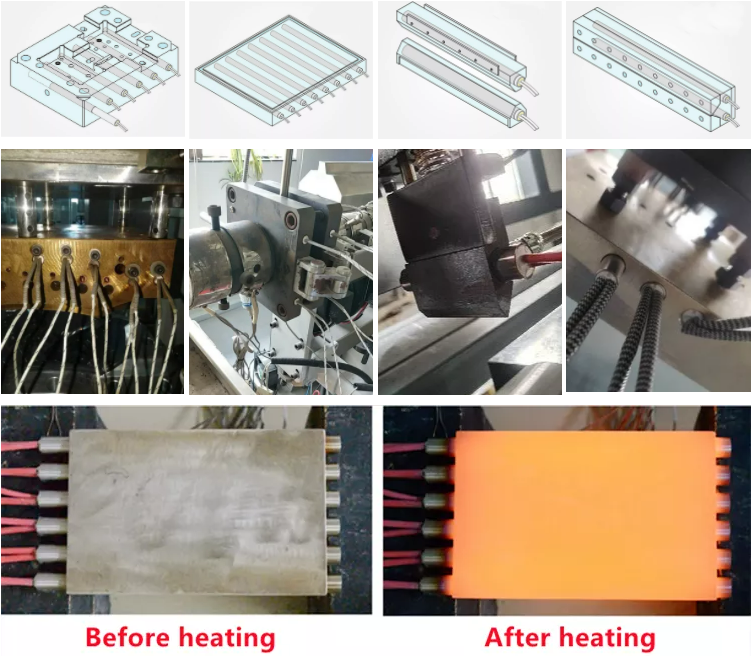

● Usually in tube form,that is used in heating applications by way of insertion into metal blocks via a series of drilled holes.

● Cartridge heaters are manufactured in two basic forms - High powerdensity and Low and medium power density.

● High power density (heating surface power 10~25w/cm²), are widely used to heat Plastic injection moulds, Moulds, Platens and so on

● Low and medium power density (heating surface power5~11w/cm²), are more suitable for packing machinery, heat sealing, labelling machines and hot stamping applications.

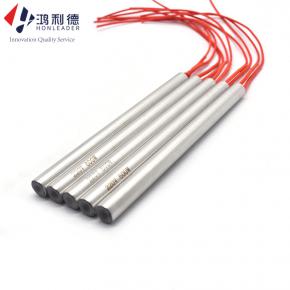

●◆ The high-quality stainless steel sheath provides long-lasting protection, even in the harshest industrial environments. Its max power density can reach up to 40w/cm², and its maximum operating temperature can reach 800℃

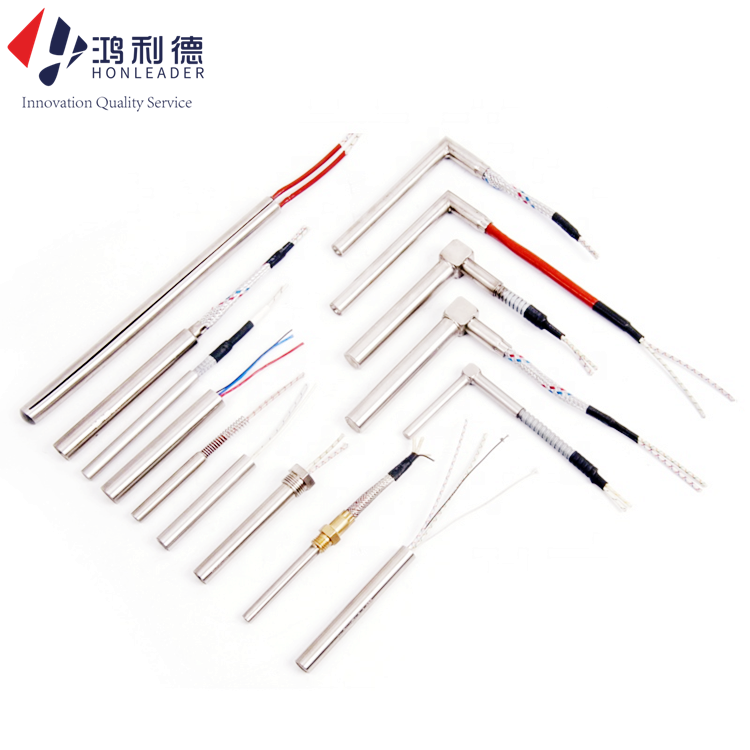

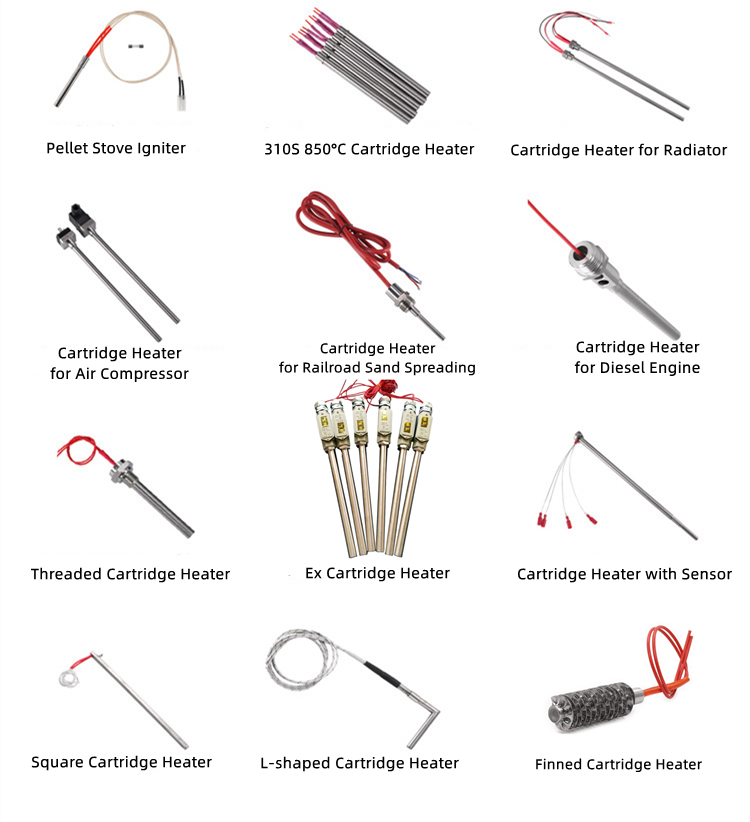

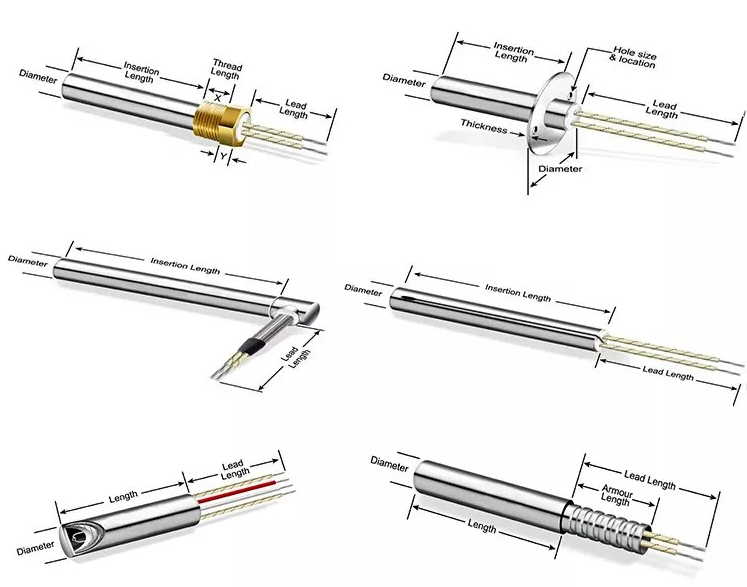

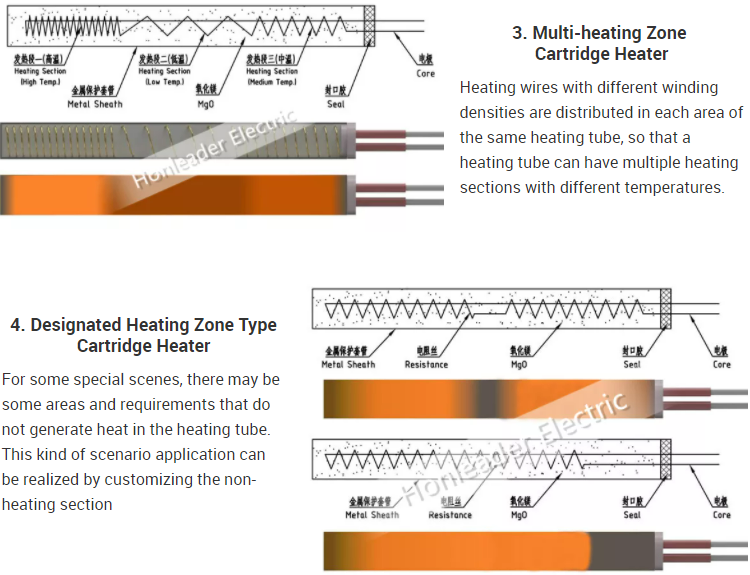

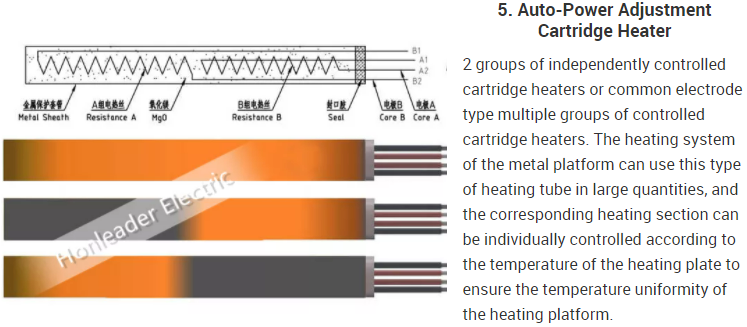

Various Cartridge Heater Cartridge Heater Available

● Injection moulding - Internal heating of nozzles ● Hot runner systems - Heating of manifolds ● Packaging industry - Heating of cutting bars,Heating of hot stamps,etc. ● Laboratories - Heating of analytical equipment,etc. ● Medical: Dialysis, Sterilization, Blood Analyzer, Nebulizer, Blood/Fluid Warmer,etc. ● Telecommunications: Deicing, Enclosure Heater,etc. ● Transportation: Oil/Block Heater, Aircraft Coffee Pot Heaters,etc. ● Food Service: Steamers, Dish Washers,etc. ● Industrial: Packaging Equipment, Hole Punches, Hot Stamp,etc. ● Extrusion molds ● Rubber molds ● Melt blown molds ● Hot press molding machiner ● Paper Industry ● Semi conductor industry ● Seal Bars ......

When you order, please specify:

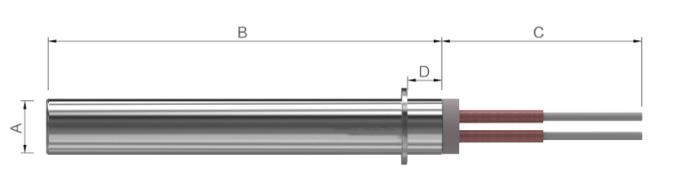

1.Diameter of electric heating tube A

2.Total length of electric heating pipe B

3.Lead length C and Lead material (Default 250mm)

4.Fixing method (None, Flange, Thread) and accessory position D

5.Working voltage and Phase line

6.Working power

7.Heating medium

8.Operating temperature

9.Mounting hole diameter, depth, accuracy.

Hits: 【Print】

Hits: 【Print】